»Dia-compact« is suitable for roughing, finishing and fine-finishing. Depending on the application and the requested Rz-value, our application engineers will customise the PCD quality and application recommendations.

Highly efficient due to fast and precise resharpening service. The LACH DIAMOND inhouse-service guarantees fast PCD resharpening and thus allows short replacement periods.

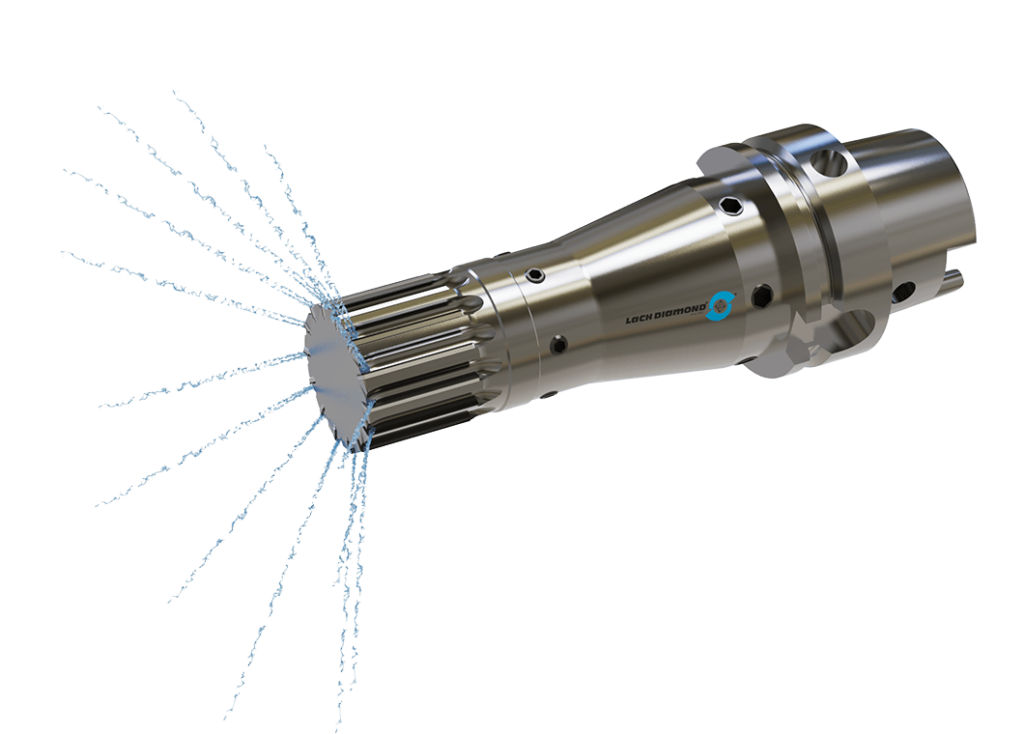

System »Cool Injection « (Pat.)

For the optimal machining of GRP, CFRP and non-ferrous metals.

This innovation of LACH DIAMOND’s founding business LACH DIAMANT directs the coolant – emulsion, oil, MMS or for cryogenic cooling – through the open cutting face of the PCD edge: directly under the chip being generated.

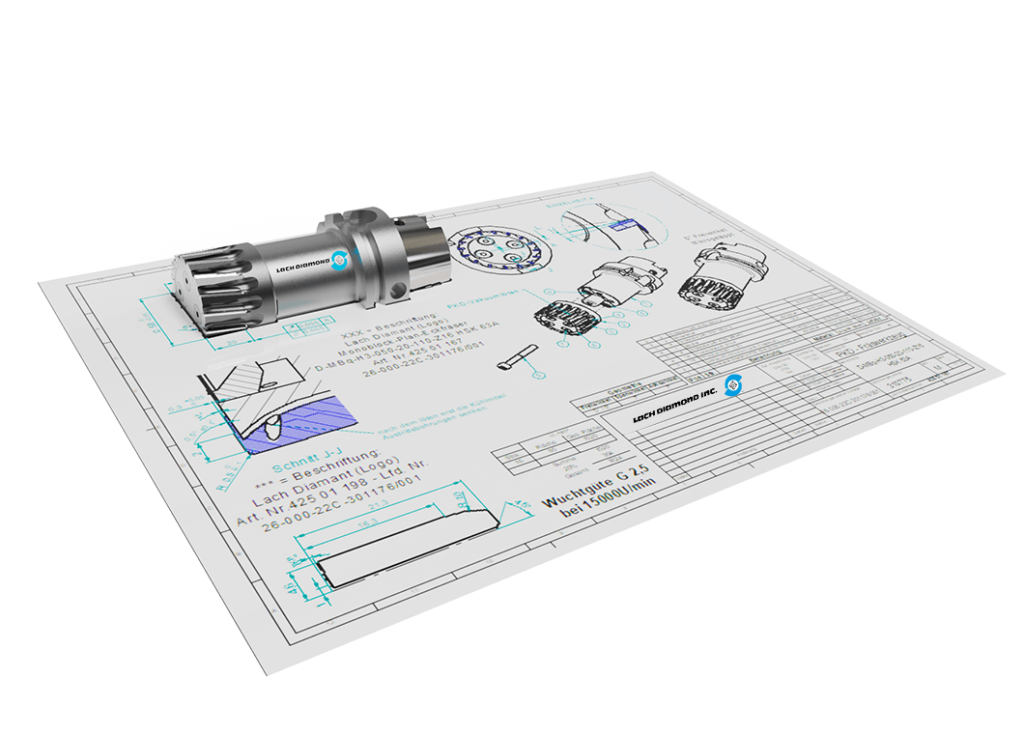

Mirror finish with natural diamond and PCD

For the super- and mirror finishing of GRP, CFRP and non-ferrous metals.

The monoblock face and square shoulder milling cutter allows the perfect finish due to the use of PCD plus natural diamond. The diamond cutting edges provide maximum perfection. What would your superfinish milling cutter be like? Get in touch with us!

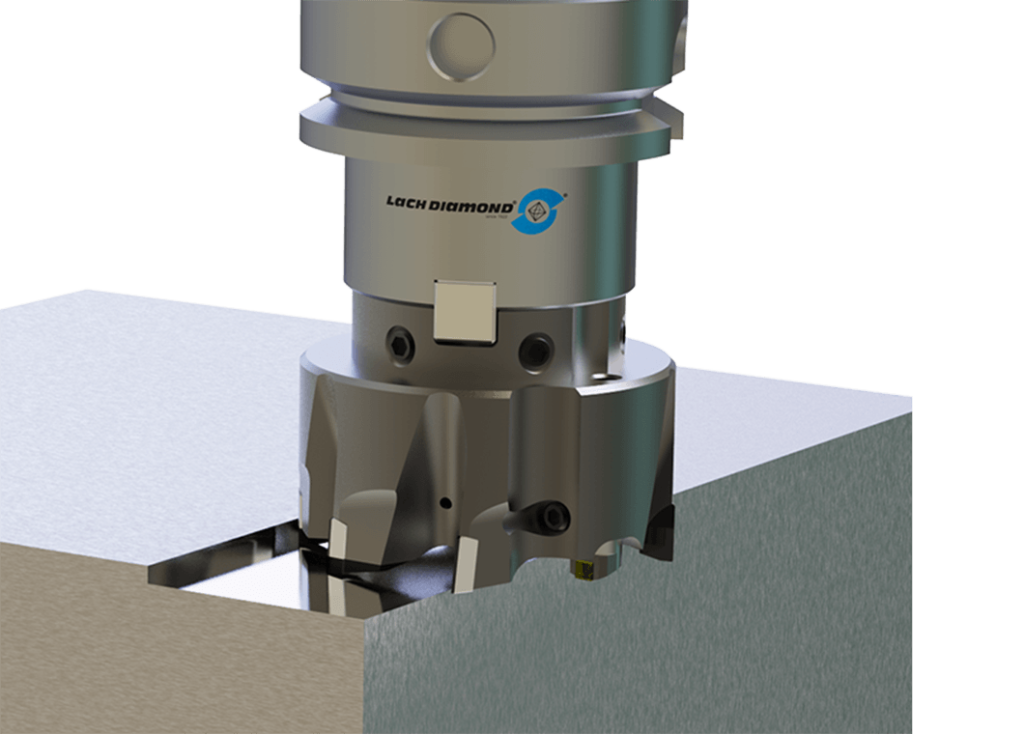

The tool holder remains – the milling cutter changes

For HSC processing of GRP, CFRP and non-ferrous metals.

The diamond milling cutter for adapting with internal cooling and optional chip breaker »plus« ensures optimal results due to ideal temperature conditions and chip removal: Long tool lives, cutting edge stability, extremely high cutting speeds (HSC) with highest feed rates. The tool holders with integrated internal cooling are specified in our catalogue.

Together with you, the LACH DIAMOND application engineers will find the suitable monoblock cutter for your application. We look forward to working with you.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA