Startpage > Industries > Automotive > Braking elements

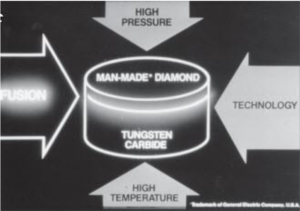

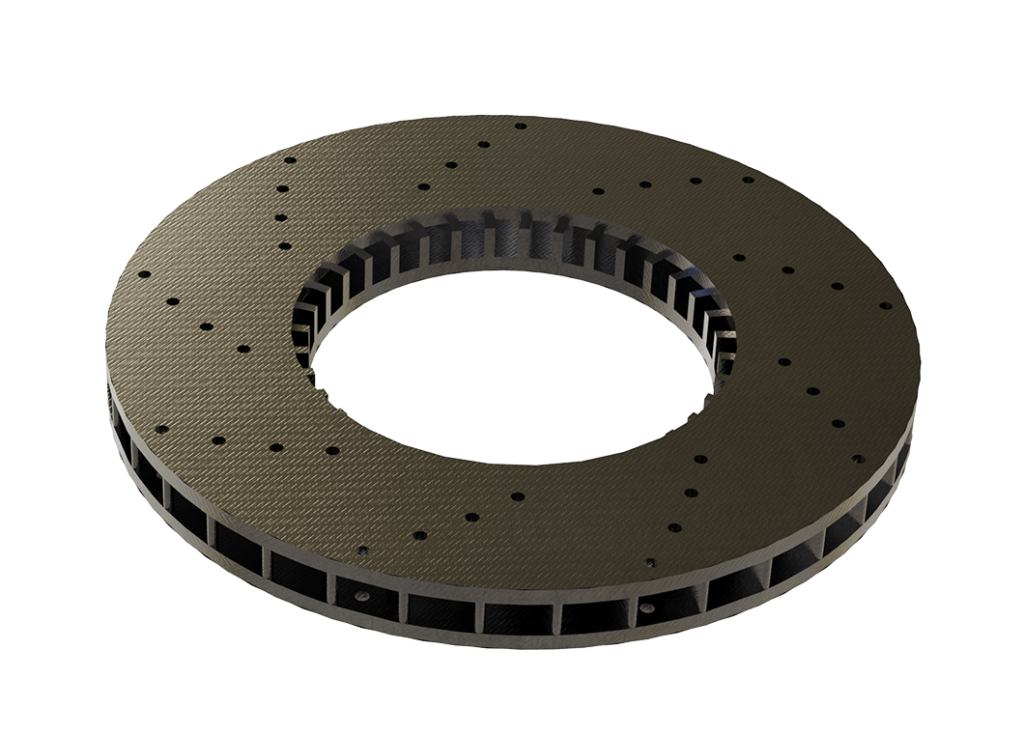

Every part of the modern brake disc is exposed to thermal and mechanical loads, still, they have to meet the highest safety requirements. PCD tools ensure an efficient and economical machining with high process reliability in series production.

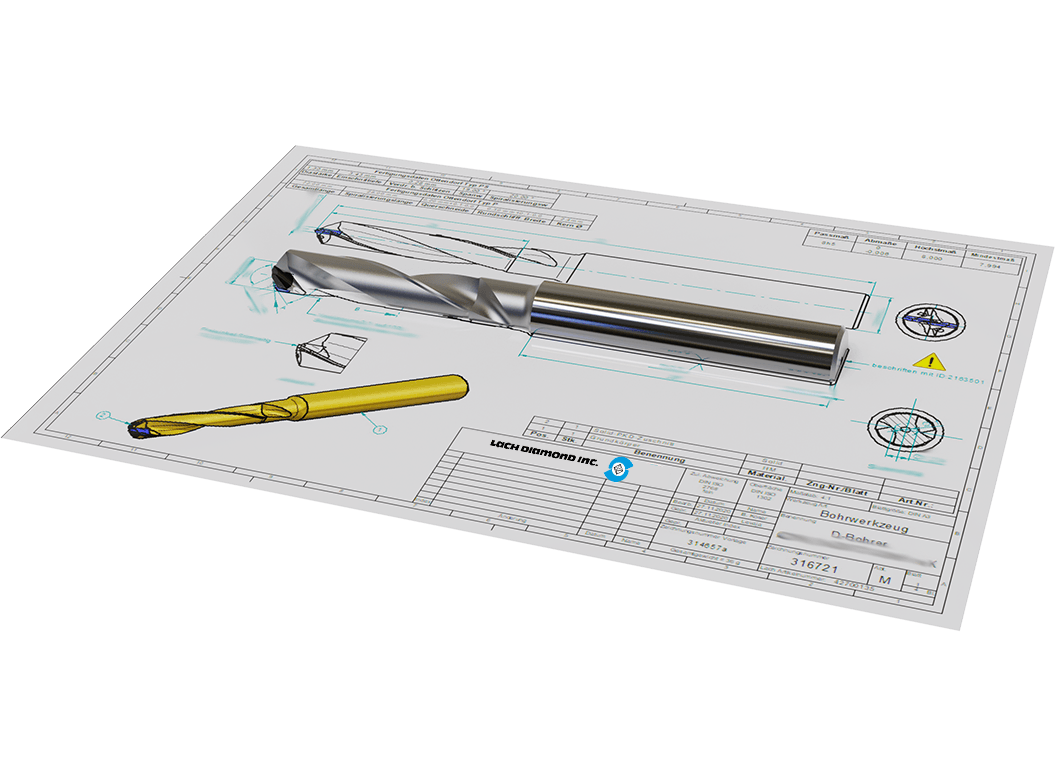

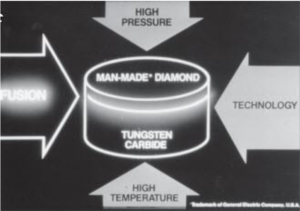

End mills with PCD cutting edges are indispensable for processing of highly abrasive materials like carbon brake discs but also GRP, CFRP, green ceramics, graphite and non-ferrous metals. The ultra-hard cutting edges allow delamination-free cuts with the desired level of quality.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your requests and requirements.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA