Startpage > Industries > Woodworking industry > Through-feed processing

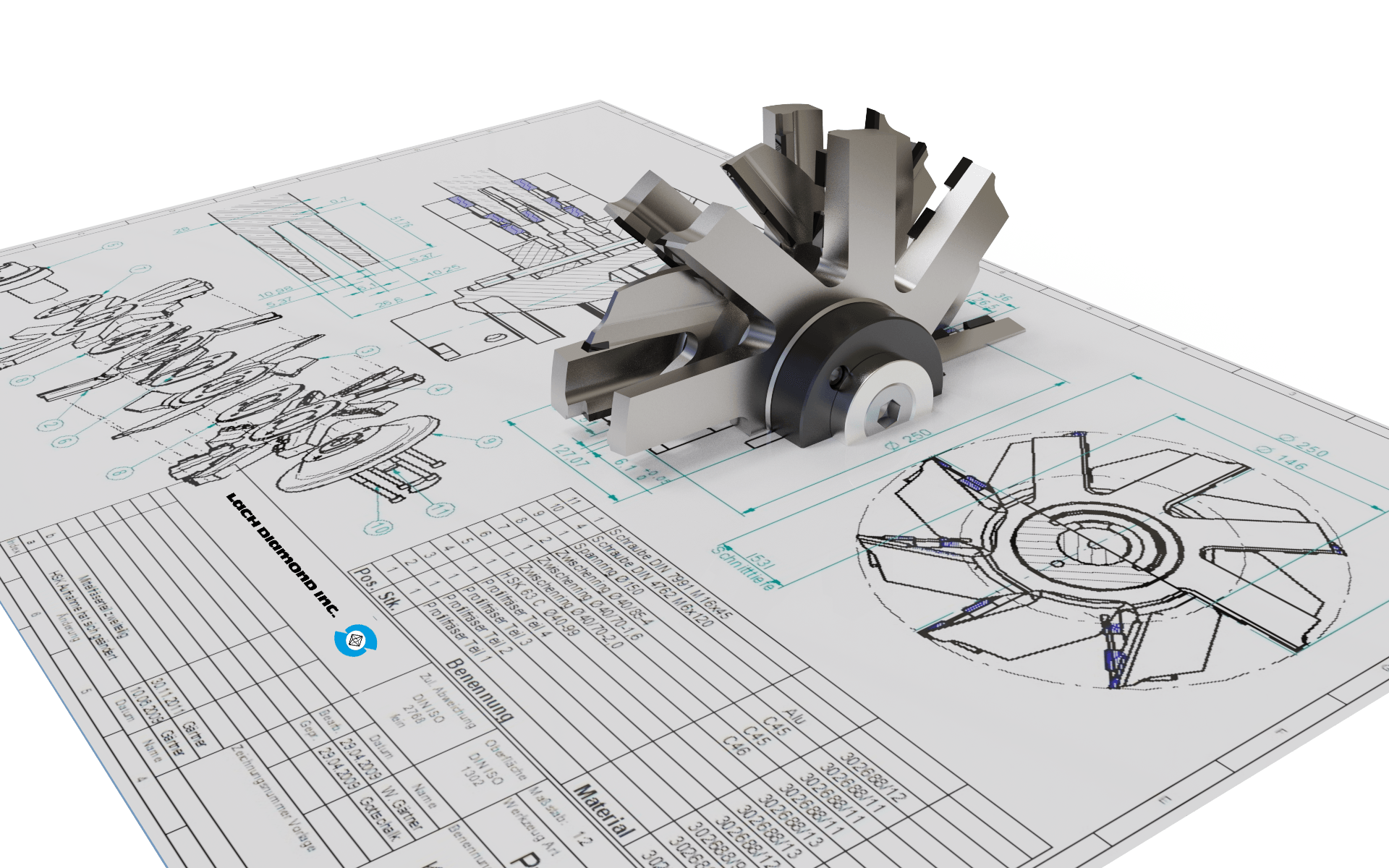

High quantities and unmanned production increase the economic efficiency by a multiple. PCD milling cutters and hoggers – precisely adapted to every application – are important components of an efficient production.

Whether exchangeable cutting edes for diameter neutral milling or extreme cutting edge geometries for zero-joint technology. The LACH DIAMOND know-how allows the realization of even the most unusual customer requests.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your request and demand.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA