Diamond and CBN meet the high demands for high-precise and efficiency-oriented production.

Diamond- and CBN-tipped turning tools or cutting inserts allow maximum cutting and feed speeds together with surface qualities reaching even ranges of the grinding technology (0,1 µm). Cost- and time-consuming process steps are significantly reduced or even completely avoided as e.g. in case of hard turning (instead of grinding).

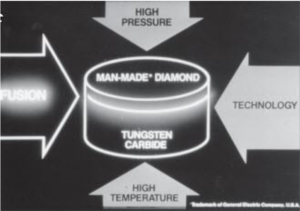

Without LACH DIAMOND the use of super-hard cutting materials would not have been possible. So, around 40 years ago, LACH DIAMANT, LACH DIAMOND’s German counterpart, was the first company in the world to use the spark erosion process in order to „form“ the man-made diamond – the polycrystalline diamond (PCD) – for the use in the tool sector – which had been impossible until then – and thus revolutionized all industry sectors. The efficient mass production in several industries like e.g. laminate flooring in the wood and plastic processing sector as well as later also in the automotive industry was born.

Since then, the application possibilities and properties of diamond and CBN turning tools have constantly been multiplied and perfected. As a consequence our customers are able to ensure process safety, quality and tool life even in case of high demanding conditions and difficult to machine materials.

To ensure that our partners are always one step ahead within their market, LACH DIAMOND offers highly competitive tools, e.g. the “full chip control” with the PCD-chipbreaker programme »IC-plus« world’s best (pat.).

“It runs and keeps running”

The PCD cutting insert »IC-plus« world’s best with active chipbreaker for finishing long-chipping aluminum alloys and all soft non-ferrous alloys.

“Turning instead of grinding”

Turning of hardened steels with newly developed CBN cutting inserts.

The demand of the automotive and supply industries for a durable cutting material for turning hardened steels has been met with the development of new CBN cutting materials like the types B610 and B600 used by LACH DIAMANT – and with highest surface qualities of e.g. Ra 0,1 µm.

Turning with PCD, CBN, CVD or MCD

Which cutting material is suitable for my application?

The cutting inserts of LACH DIAMOND offer the right cutting material for every processing with the corresponding cutting insert. Quality made in USA.

Along with the manufacturing of our standard products we develop tailor-made solutions for your specific application. Special dimensions are manufactured according to your request and demand.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA