Startpage > Industries > Automotive > Crank shaft and camshaft

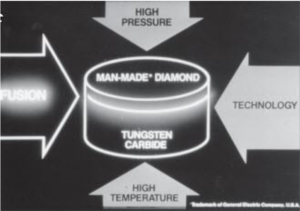

The grinding of camshafts, crank shafts and balance shafts requires maximum precision and economic efficiency. The non-circular shape and the required surface quality are harmoniously created by perfectly matching CBN grinding wheels.

The quality of wear parts is a key factor in the process chain: PCD-tipped bearing shells, work rest blades, steady rest blocks etc. will not only reduce production costs, they also improve the quality of the workpieces.

The non-circular grinding process requires maximum precision with regard to the shape to be generated and the required surface quality. LACH DIAMOND grinding wheels ensure highest process reliability for an optimal grinding process of camshafts and crank shafts.

Wear protection components can be found in all process steps of the production chain. They have a significant influence on the quality of the products to be manufactured – for example through the bearings of shafts in your grinding process.

We look forward to meeting your demands with an innovative and economical solution. We think out of the box and know your process chains. Let us find a solution together: LACH stands for solution.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA