PCD (polycrystalline diamond) consists of diamond crystals which are sintered into a bond matrix (cobalt or tungsten) at high pressure and at high temperatures. Between the individual crystals there is a metal binding phase which is mainly applied to carbide body.

Due to the random diamond orientation the PCD layer is formed as an isotropic body which has no preferred cut direction.

PCD closely approximates to a monocrystaline diamond in terms of hardness and its abrasion resistance outperforms carbide by a hundredfold.

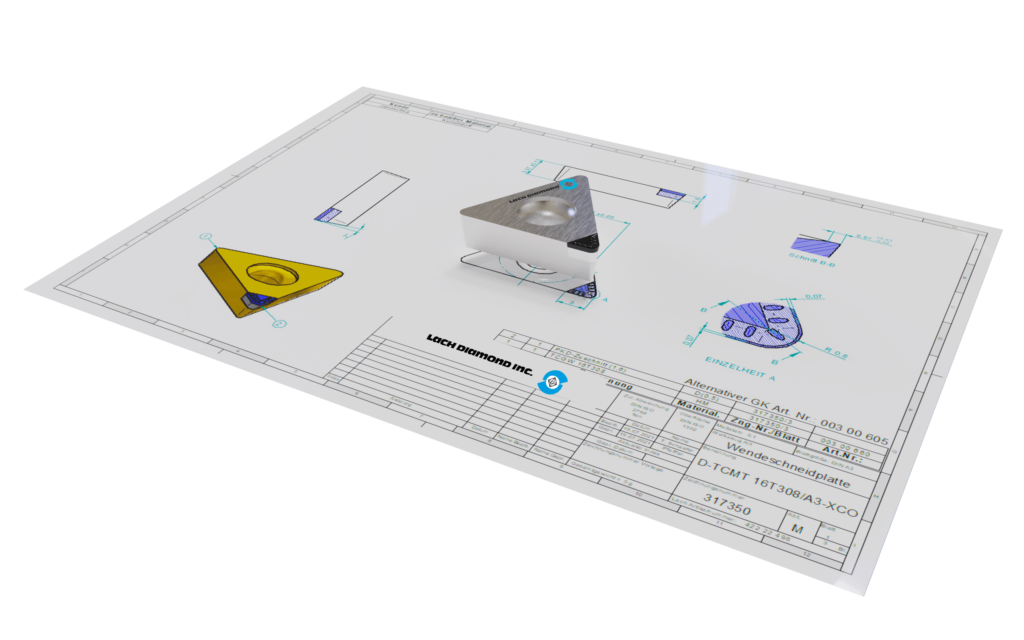

Turning tools with PCD cutting edges are successfully used for the processing of aluminum, non-ferrous metals and composite materials, preferably in series production and for abrasive materials.

The main area of application of CBN cutting inserts is finish turning of hardened steels and grey cast iron.

CBN (cubic boron nitride), the hardness of which is only exceeded by diamond, has been developed for cutting materials whiche cannot be processed with PCD. Turning or milling is not a problem for CBN cutting inserts because this cutting material has an extremely high thermal hardnes

MCD is very similar to natural diamond. Both have the same physical properties and an octahedral growth. Similar to synthetic diamonds MCD are made of graphite using the high-pressure and high-temperature process.

MCDs are synthetically produced diamond blocks which are shaped to rods by sawing or cutting. Here the cutting direction runs along the direction of growth of the diamond.

Due to the production process MCDs have a direction of growth.

After the edge calibration by cutting or sawing, the rods are cut to the corresponding length.

Due to the direction of growth, please make sure that the rods are correctly fitted in the dressing tool. Depending on the MCD manufacturer, the wear resistance is higher when using a linear or rhombic mounting types.

In complex applications standardised tools quickly reach their limits.

Is there a suitable solution for your specific application? We will be pleased to develop your customised special tool.

Please contact us!

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA