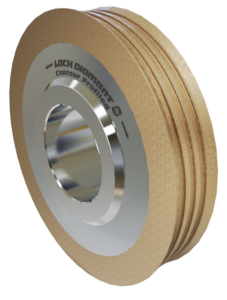

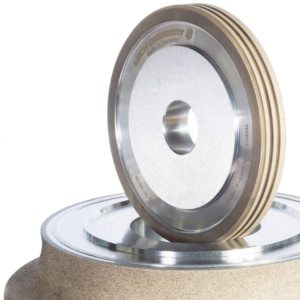

A grinding wheel with a metal bond for deep grinding – hitherto almost unthinkable. For the first time, newly developed bond variations are available for profiling during the deep grinding of carbide, high-alloyed steel, ceramics and, in a special specification, even unhardened steel. What was, up to today, only possible in time-intensive conventional grinding procedures or with several diamond and CBN grinding wheels, is now accomplished with only one profile grinding wheelknown as »contour-profiled«:“One for Everything“.

The innovative metal bond allows for something never thought possible: Contour grinding from the solid – and with profile depths of up to 15 mm(!), e. g. bottom blades or profile blades – there is absolutely no impact on tool life, even at full feed rate.

The result: Repeatable precision profile cuts in mass production. The advantage is obvious: Significant reductions to a fraction of the original total cost.

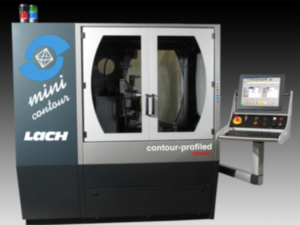

The highly developed »contour-profiled« grinding wheels can even be re-sharpened: For this purpose, LACH DIAMOND developed a special sharpening machine which can produce high-precision concave and convex profiles from 2 to 4 µ. In addition, «mini-contour» machines are available for service or purchase, both for manufacturers and end customers.

»contour-profiled« diamond and CBN grinding wheels and the «mini contour» sharpening machine with EDG-procedure are among the highlights of IMTS in Chicago. All innovations will be presented at the LACH DIAMOND booth. The LACH DIAMOND team is looking forward to your visit – Booth 43-2054 (West Building) or you can get information in advance from office@lach-diamond.com or at www.lach-diamond.com.