»CBN-Duo-power« – „Turning instead of grinding“

Turning hardened steel with newly developed CBN-inserts

Already in 1974 the diamond tool manufacturer in Hanau achieved a technological breakthrough in machining hardened steels with a hardness starting from 58-60 Rockwell (HRc).

This was made possible through the development of polycrystalline cutting materials on the basis of cubic boron nitride (CBN).

CBN – even though inferior to diamond in regards to hardness – features a significantly higher thermal stability than diamond (diamond = approx. 700°C / CBN = approx. 1500°C) ; the reason being that the spark (1000°C) which emerges during steel machining would quickly melt (diffuse) the diamond that consists of carbon.

Until the discovery of polycrystalline CBN cutting materials, hardened steel could only be machined by laborious and time-consuming grinding processes. The slogan „turning instead of grinding“ which was characterised by LACH DIAMANT already in 1974, was a technological sensation even at that time. Long hours of grinding were reduced to a few minutes of turning!

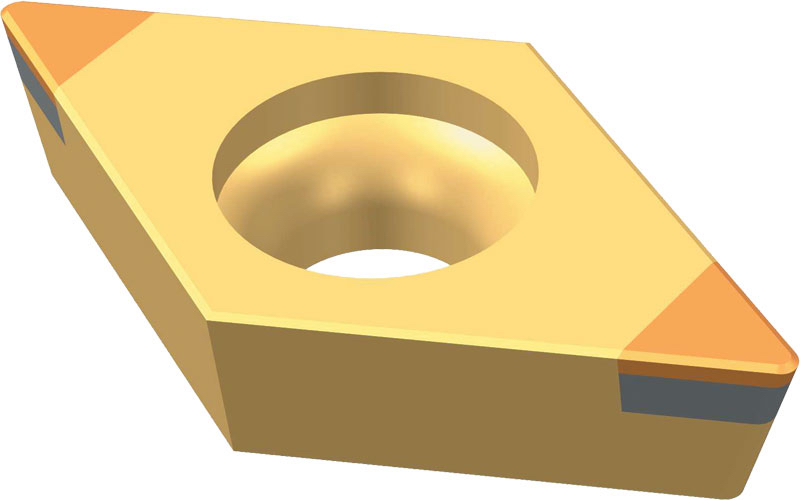

Now, LACH DIAMANT doubles this efficiency by offering an insert with 2 tips: »CBN-Duo-power«.

The development of new CBN cutting materials like the types B610 and B600 used by LACH DIAMANT met the demand of the automotive and component industry for a cutting material with long-term stability for the turning of hardened steels – and this with highest surface qualities of e.g. Ra 0,1 µm.

»CBN-Duo-power« inserts type B610 or rather B600 are especially recommended for finish turning:

- with interrupted and continuous cut especially in tool steels and case-hardened steels as well as powder-metal alloys

- of components like gears, cardan shafts, valves, belt pulleys and even of brake discs and brake linings and for turning sprayed metal alloys etc.