LACH DIAMANT, LACH DIAMOND’s German counterpart, offers the optimal machine concept for the service and up to the complex production machine – with an easy handling system – for the processing of all PCD tools in variety of industry sectors.

All machines are developed in cooperation with our own production facilities and can be found in all production plants.

Today, LACH machines are operating all over the world. It is still our objective to pave the diamond tool’s way to new production sectors and new countries. Therefore, it is a specialty of LACH to support other companies worldwide in establishing a sharpening service for diamond tools. This assistance goes far beyond the classic operation of a diamond erosion machine and includes everything necessary for the service of a diamond tool.

A high removal performance allows the economical processing of standard and special PCD tools

There is no need for CNC knowledge. You will learn the processing of complex diamond tools within a few days

LACH automatic sharpening machines are well-known for their long lifetime and just in case – are easy to repair

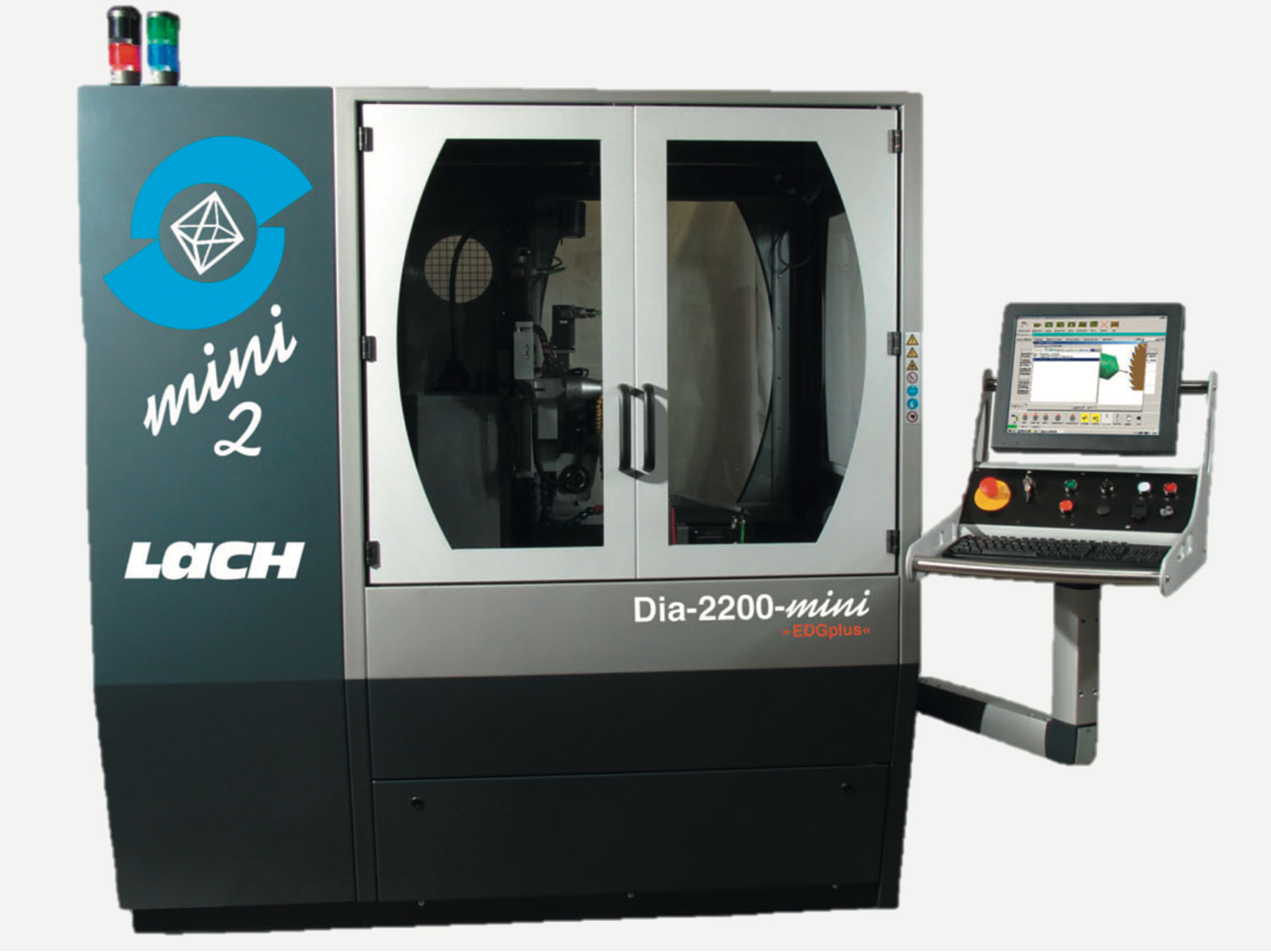

The »Dia-2200-mini« is the ideal machine for sharpening services. Regardless of the type of PCD tools you will receive, the “mini 2” is able to meet all dimensions.

The »countour-profiled« is the specialist for dressing metal-bond diamond and CBN grinding wheels. It allows highest profile accuracy with hitherto unknown grain protrusion.

When purchasing a LACH machine we shall give you comprehensive advice on all issues regarding diamond tools. At your request we will supply you your own „turn key“ sharpening service. All you need are premises and staff.

LACH DIAMOND INC.

4350 Airwest Drive, S.E.

Grand Rapids, MI, 49512 USA